Chocolate Purveyors is a blog series where we connect and discuss everything chocolate with both makers and enthusiasts. This discussion is with Anna Broto Divorra, quality manager at Blanxart.

It was in April of 1954 when the master chocolatier Francesc Agrás embarked on a long journey through the best patisseries and confectioneries in Europe. His passion for excellence in artisan confectionery was the seed that led to the founding of one of the most renowned Catalan chocolate factories: Bombons Blanxart. It all started in a modest workshop in the neighborhood of Les Corts (Barcelona) and feeding a dream: bringing the best cocoa beans from Ghana, Congo, and Guayaquil to chocolate.

Do you remember your first experience with real chocolate? What was it?

My first experience with real chocolate was the first day I started working in Blanxart. I found a wonderful team with very high knowledge of chocolate making and a great product.

As the quality manager of Blanxart, what does your day look like?

Every day is unexpected in a small company. It is challenging to control every single step of the bean-to-bar process at the same time that you develop new products, you travel to origin or you answer all your customers doubts.

How did you end up in the world of craft chocolate? What did you do before?

I studied Bachelor’s Degree in Food Science and Technology and ended up 10 years ago in Blanxart doing my Practicum. I was a young girl creating a quality department in an artisan factory, we both have evolved together. I’m still learning every day!

What has been your biggest challenge in working in the craft chocolate industry?

My biggest challenge has been explaining to everyone why single-origin craft chocolate is special and different. It’s gratifying to see how people can quickly understand it doing a blind tasting.

What is Blanxart's Bean to Bar process?

Everything starts with selecting interesting cocoa beans in small cooperatives in origin. We buy cocoa beans from 7 different origins. When cocoa arrives at Blanxart we turn cocoa beans into cocoa liquor with three steps: direct fire small batch roasting, winnowing, and milling. After that, we elaborate the recipe and we conche it for 48h. When having a perfect flavor and texture development we temper, mold and pack it.

How do you select the cacao you work with?

We select cacao with personality (with aromatic complexity) coming from reliable suppliers.

What chocolate are you eating from other makers these days?

None in particular. None in particular. Since I started working here, I have always eaten Blanxart chocolate. I love the process and I love the result.

For someone trying a Blanxart chocolate bar for the first time, what chocolate bar would you give them to try?

I’ll first give them to try Peru 77% chocolate bar as it has a very interesting profile ideal for all dark chocolate consumers.

What does the future hold for Blanxart hold?

A lot of chocolate!!!

We want to thank Anna for taking the time to answer our questions and the Blanxart team for making this happen. We hope you learned more about Blanxart Chocolate and its process.

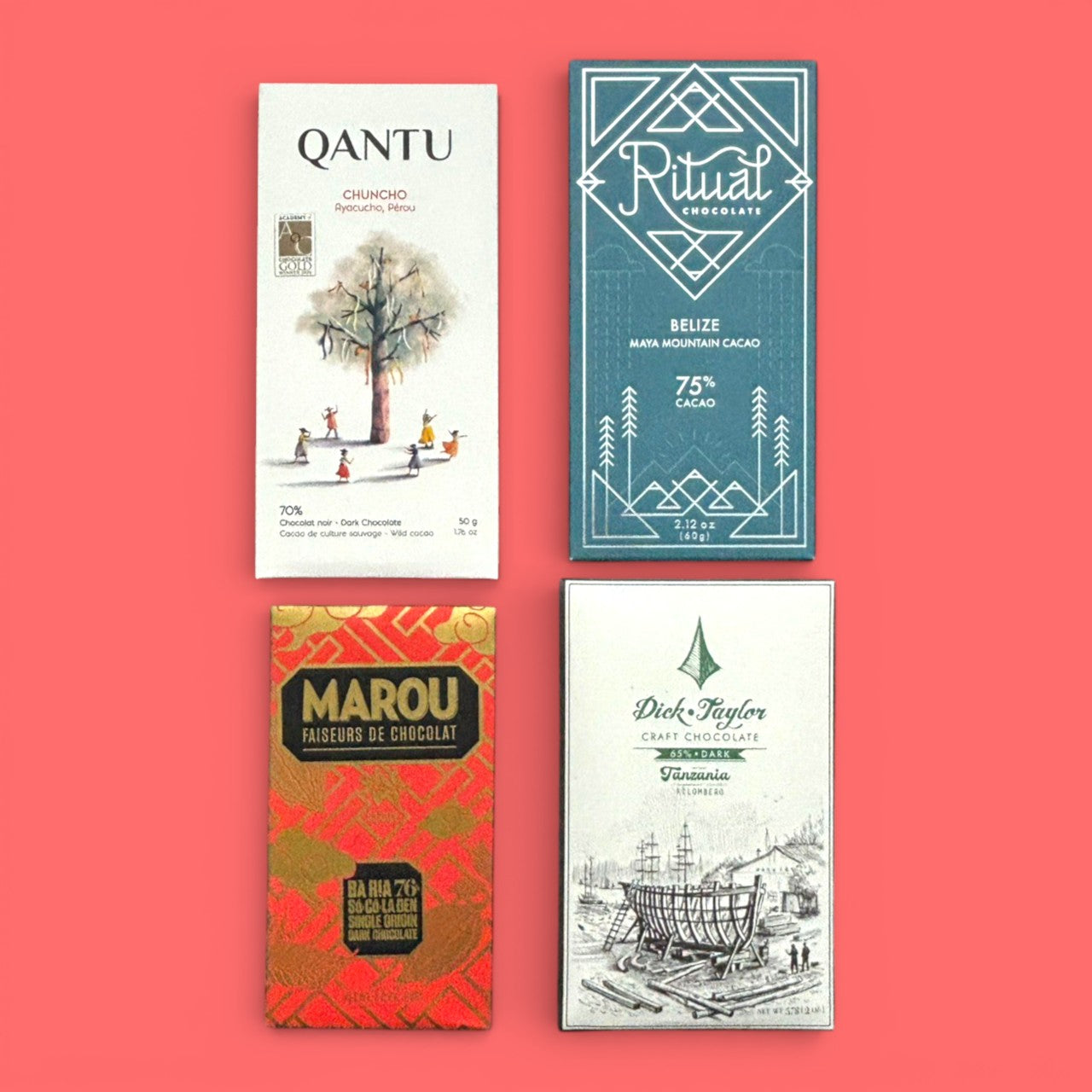

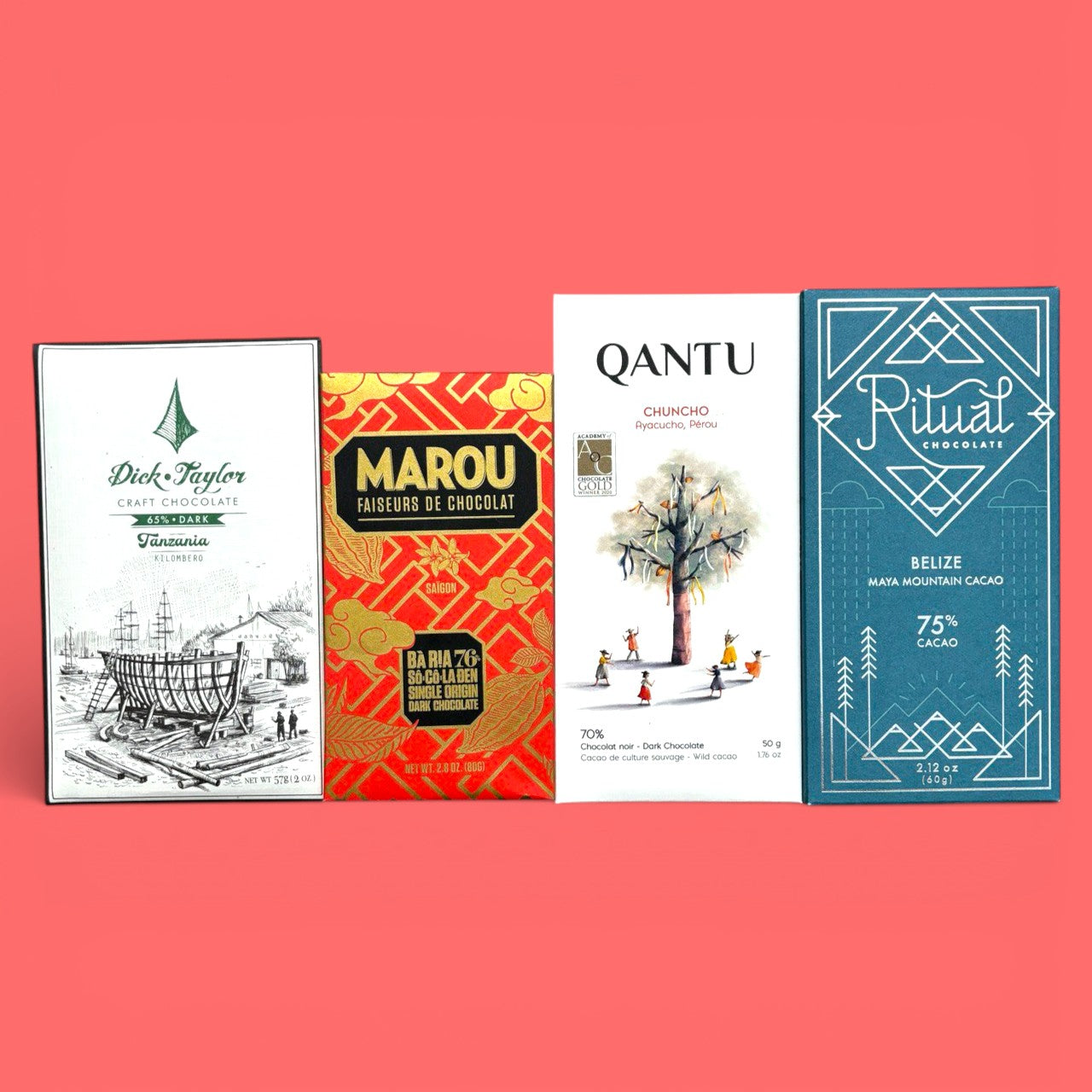

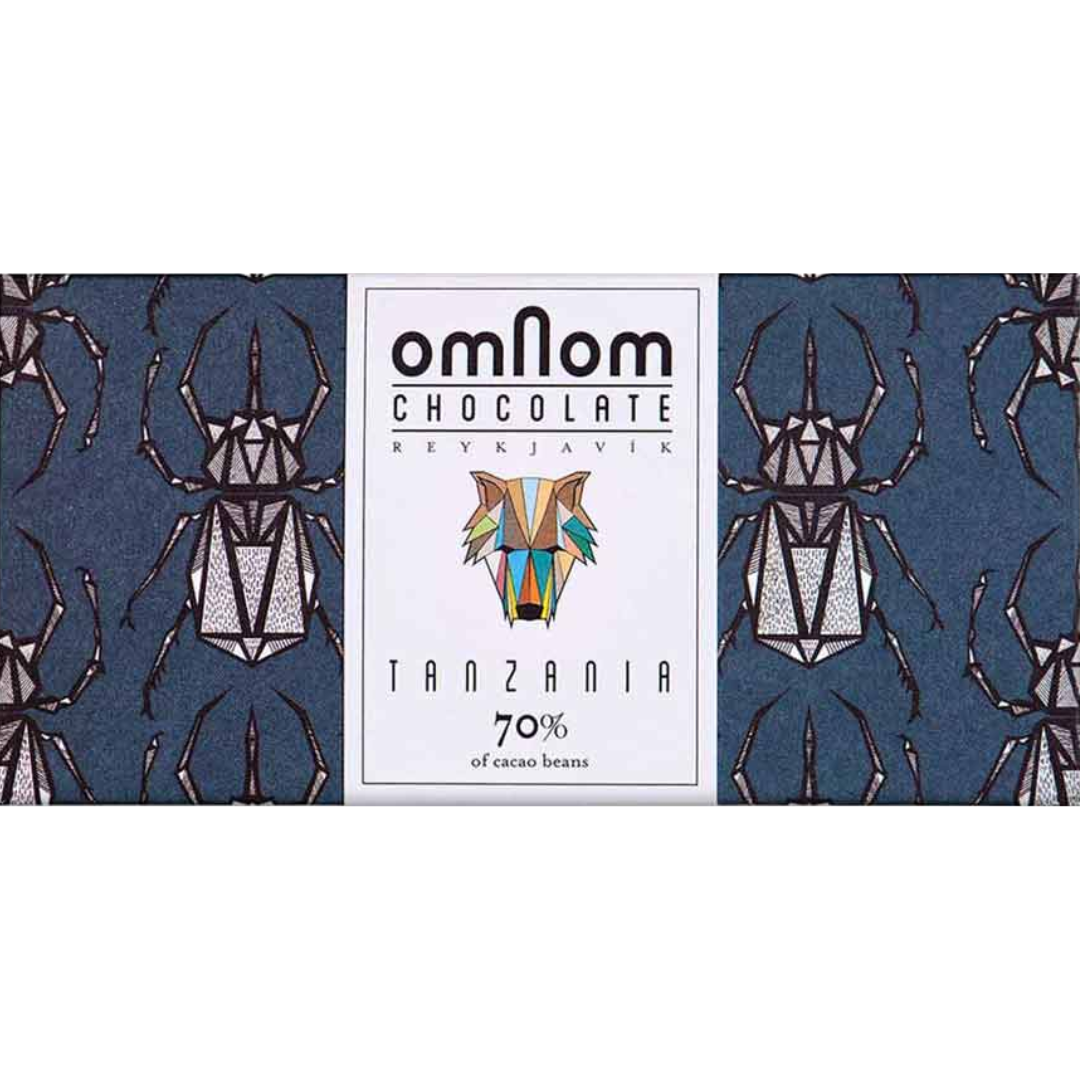

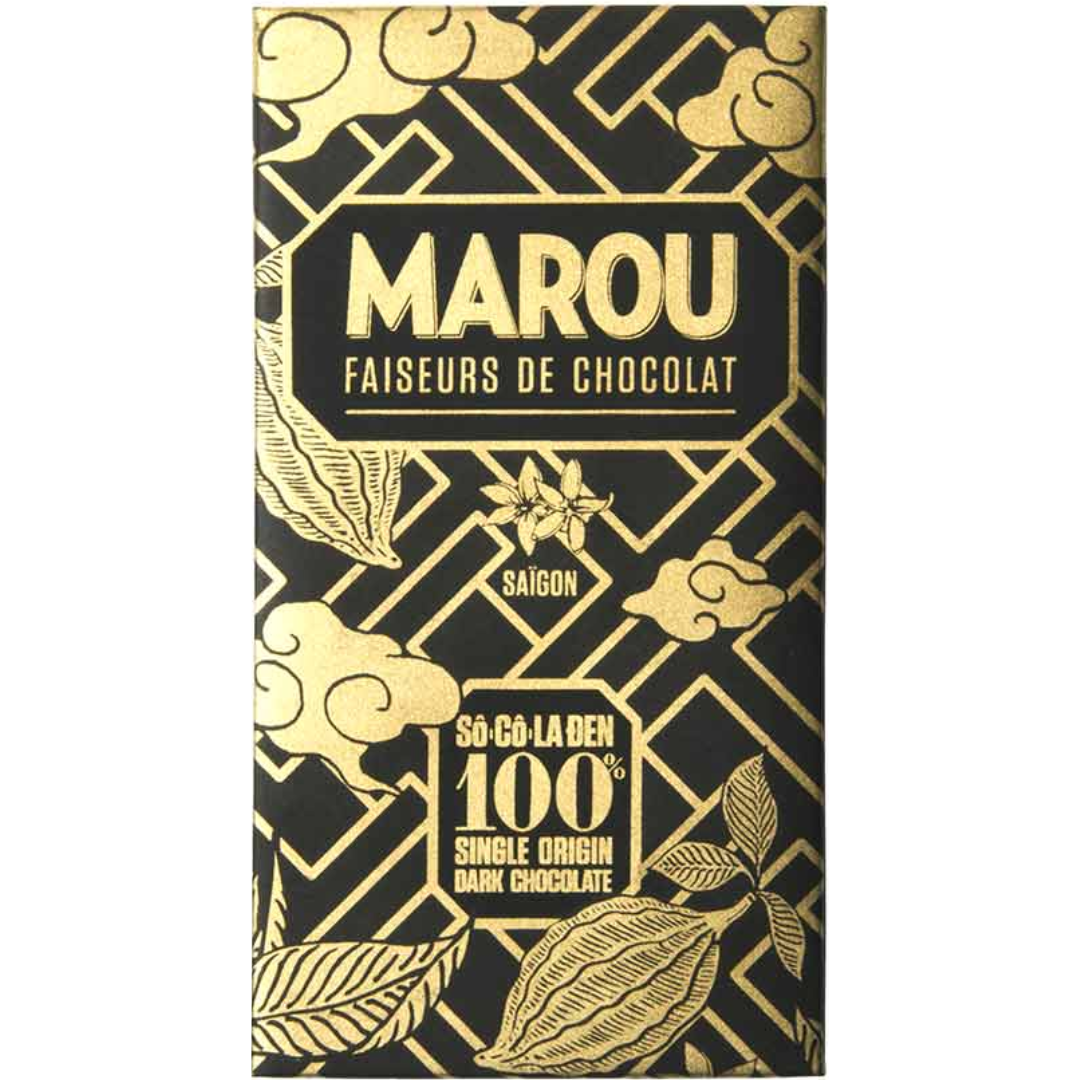

To get started with gourmet chocolate, start with our Kekao Box. We search the world for the finest chocolate bars and bring them right to your doorstep monthly. From rich dark Peruvian chocolate bars to new start-up chocolate bars on the come-up, you never know what you'll get inside the box!

If you want to try a few bars, check out our online chocolate store.

If you have any questions regarding this blog, our Kekao Box, or the chocolate bars we carry, feel free to contact us. Keep up with us by subscribing to our newsletter or following us on Instagram.