Chocolate Purveyors is a blog series where we connect and discuss everything chocolate with both makers and enthusiasts. This discussion is with David Menkes, co-founder of LetterPress Chocolate.

LetterPress Chocolates' story starts in high school, where founders David and Corey met. Their first experience with cacao was in 2011 when they traveled to St. Lucia on vacation and happened to stop at a cacao plantation where they got to taste the pulp from cacao pods for the first time. Today, LetterPress Chocolate has its very own factory where you can visit and even complete a tour with tastings.

Photo Credit LetterPress Chocolate

Do you remember your first experience with real chocolate? What was it?

Baskin Robbins with my dad when I was maybe 5 years old. I asked for a scoop of vanilla and my dad said “vanilla’s not a flavor!” and had me get chocolate instead. I guess it was drilled into me at an early age. Funny enough, whenever I drink a milkshake now, I usually get vanilla these days.

What type of experience can someone expect tasting LetterPress Chocolate?

To realize that chocolate isn’t simply an ingredient in a dessert or a candy bar to be wolfed down - that it can be an experience. That no matter what is going on in your life, you can have this one moment to yourself. It’s not our chocolate, it’s yours.

Do you prefer hot chocolate or coffee in the morning?

Definitely hot chocolate - I don’t drink coffee normally.

Photo Credit LetterPress Chocolate

What makes Mocha 70% Bar different compared to other chocolate/coffee bars?

Well, I’m not a super big coffee nerd or anything but I noticed that every coffee chocolate bar I’d ever eaten was super bitter and astringent. And I think that’s because most makers grind the coffee beans directly into the melanger. I don’t agree with that - you’re not supposed to eat coffee, but drink it.

So that got me thinking about the extraction process. A lot of coffee snobs will tell you that a pour over with the proper water temperature is critical, and we spent a lot of time talking with Derek and Will over at Alibi Coffee here in LA. We worked for a while on the problem and since you can’t use water in chocolate, the oils from the coffee beans would have to be extracted some other way.

So we tried cocoa butter instead of water and we found that there was little to no bitterness or astringency because you’re leaving all the fibers in the grounds. This resulted in us being able to fine-tune the amount of coffee going into each batch, and we could change the amount on the fly during the tempering step. The result is a much more nuanced and mild coffee flavor without any of the drawbacks of grinding coffee beans into the chocolate. It’s definitely one of our most popular flavors.

Photo Credit LetterPress Chocolate

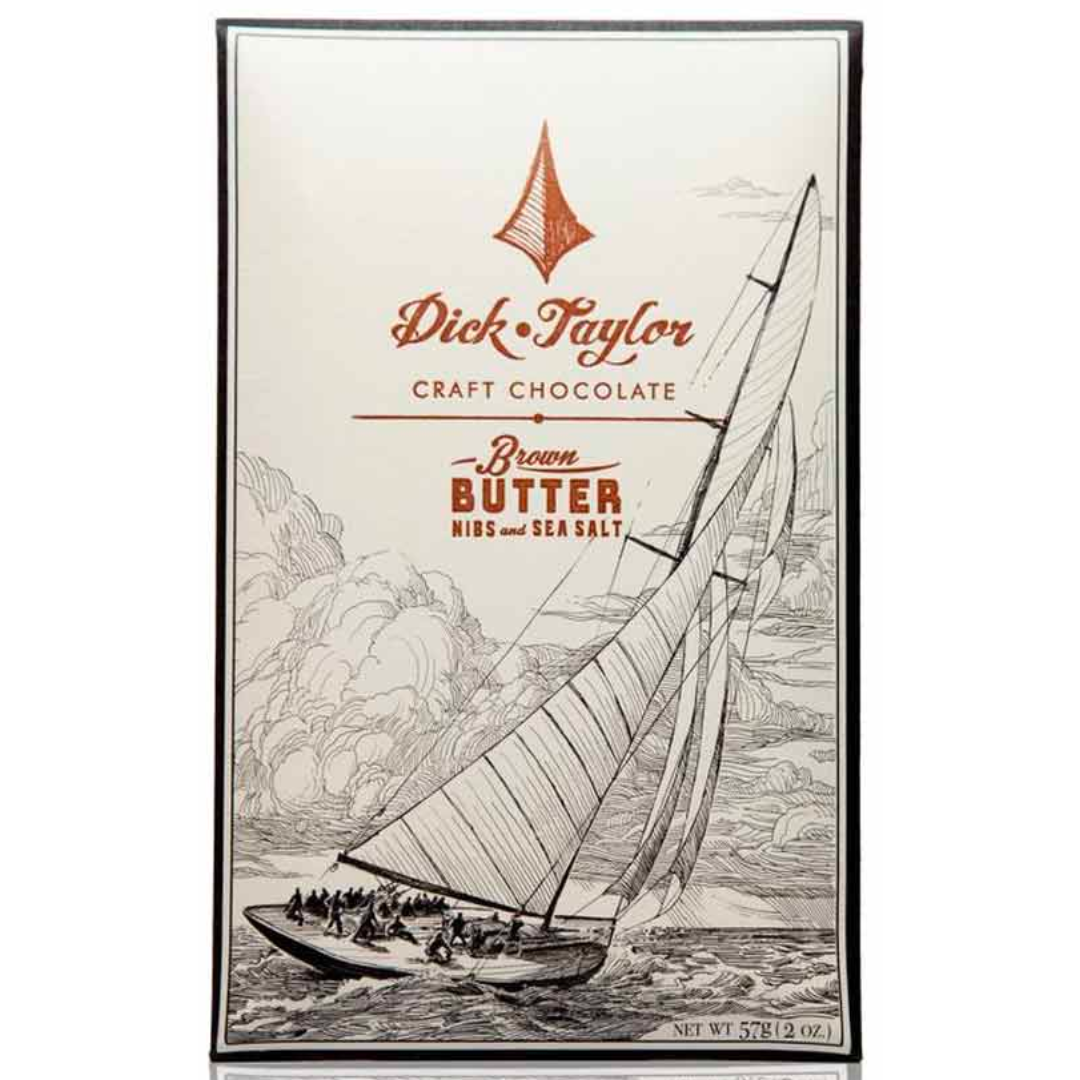

How much does packaging matter in craft chocolate? What is your design process?

What can someone expect from one of your factory tours?

The tour is split into three sections. First, we spend some time talking about the work of the farmers - how cacao is grown, pollinated, and harvested, and then into fermentation and drying and the premiums we pay to the farmers and co-ops we work with. Then we go into the factory and see how we roast, crack, winnow, and grind our chocolate with our custom-made machines (we even have a mini impact cracker!). Then we talk about tempering and packaging. We finish by coming back up to the front and sample a variety of single-origin chocolate bars so that we can taste the differences between each region. The tours are typically 45 minutes long and come with lots of samples along the way!

How much did your trip to St.Lucia encourage you to dive into craft chocolate?

Back in 2011, we were driving around the island on vacation, not thinking about chocolate at all. Then we stopped on the side of the road for lunch and saw these funny looking trees with these funny looking pods on them and I asked one of the locals what it was. “Oh, that’s a chocolate tree,” we were told. Chocolate tree? Then the guy took us across the street to check out the fermentation boxes and drying trays, and I was shocked by seeing these funny looking little beans and learning that’s where chocolate comes from.

We came back to LA and searched around for stores that carried chocolate, and one of them, The Cheese Box at Wally’s in Westwood, had a great selection. I told one of the employees there that we were new to craft chocolate and asked for a recommendation. We were handed a Porcelana bar by Bonnet and I think it was about $20. I’d never paid that much for a chocolate bar before! But we took it home and spent some time reading about the company and the origin of the cocoa beans, and then we started to eat the chocolate - and my world was forever changed!

I had no idea chocolate could taste like that. Normally I always found supermarket chocolate far too sweet and most of it has a weird burned or plastic taste. But this was something entirely different. We kept buying more bars, and I was working at DreamWorks Animation at the time and bringing in the bars we were done with to share with coworkers.

Photo Credit LetterPress Chocolate

Soon I became known as Chocolate Dave and so many people were stopping by my desk to try chocolate that HR got involved. “Look, you’re distracting people on your floor and coworkers around you. We’re not telling you not to share chocolate, but maybe you could do it during your lunch break?” So I set up an email alias that we called the DreamWorks Chocolate Society, and once a week (usually Mondays) after lunch, a group of us would sit down and taste through 5 or 6 different chocolate bars. Everyone pitched in $5 to cover the cost of the chocolate. One day, one of my supervisors stopped by to ask for some chocolate and asked, “Hey what was that really awesome bar we tried a few months ago from Peru? Think it had a green label?” “Uhh, I have no idea.” She then said to me, “You should be writing all these down! Start a blog!”

So I went home and my wife and I started Little Brown Squares, a blog dedicated to bean-to-bar chocolate. After a year or so, we had over 5000 followers on Facebook (we didn’t post on Instagram back then) and chocolate makers started sending us their bars to review! I guess they liked our methodology and photography. Anyway, this led to me writing several articles for Chocolate Connoisseur Magazine, and covering the Northwest Chocolate Festival for them. This was 2013. While there, we were interviewing several makers and asking who was making chocolate in Los Angeles. To our surprise, nobody was!

Around this time, I was thinking of shooting a documentary about cacao and I called up my old producer from when I used to work at Disney, as I knew he was in Guatemala running a hardwood farm. “Hey Juan, what do you know about cacao?” “I’m growing it!” “Wait, what? Really? Are you looking for investors?” “Uhh, I guess, why don’t you and Corey come down and check it out?” So Corey and I planned on flying down to Guatemala to check out Juan’s project, Izabal Agroforest. But before we went down there, I realized I knew next to nothing about cacao.

Photo Credit LetterPress Chocolate

This led me to find out about Madre Chocolate’s Cacao Bootcamp that they were offering in early 2014. I signed up and flew out there to learn about growing cacao, grafting, fermentation, and even making chocolate from bean-to-bar. I actually didn’t like the chocolate-making part at all - too messy. I didn’t like getting my hands dirty (I don’t know why we weren’t wearing gloves) so I didn’t have any real interest in making chocolate myself. I was more interested in the cacao.

So Corey and I flew down to Guatemala and spent time driving around Coban, where there’s plenty of cacao everywhere, then on over to Izabal Agroforest. Juan walked us through his sustainable farming methodology and we fell in love with the farm immediately. I bought cacao beans from many different farmers and co-ops while we were in Guatemala, and I brought them all back to LA where I played around with roasting the beans in our home oven.

We peeled every bean by hand - a process that took about an hour per ounce per person - so 10oz of cacao took us 5 hours to peel. We used a molcajete to grind the paste and added sugar and the result was…well, terrible. I realized we needed to grind much longer than what I could do by hand, so we bought a little wet grinder and a crankandstein hand cranked bean cracker, and a paint bucket winnower from Chocolate Alchemy. At least now we were able to grind the chocolate smooth, and I bought some molds and we were making about 20-30 bars at a time. I was still working at DreamWorks so I brought some samples in and had our group taste them blind. I asked the group what they thought of the samples - and I asked, “What’d you guys think of #5?” “Oh, that was hands down the worst one!” “Yeah, I hated that one!” “I thought it tasted like moldy socks!” And, well, #5 was our bar.

Photo Credit LetterPress Chocolate

So, that wasn’t exactly encouraging. Remember, this group had been tasting some of the best chocolate in the world, consistently each week, for almost 2 years straight. We literally had a high bar set for where we needed to be. In fact, I think it was about 6 months of making batches pretty much every day until we made a batch that people found edible. After that, we were able to start selling every bar we made.

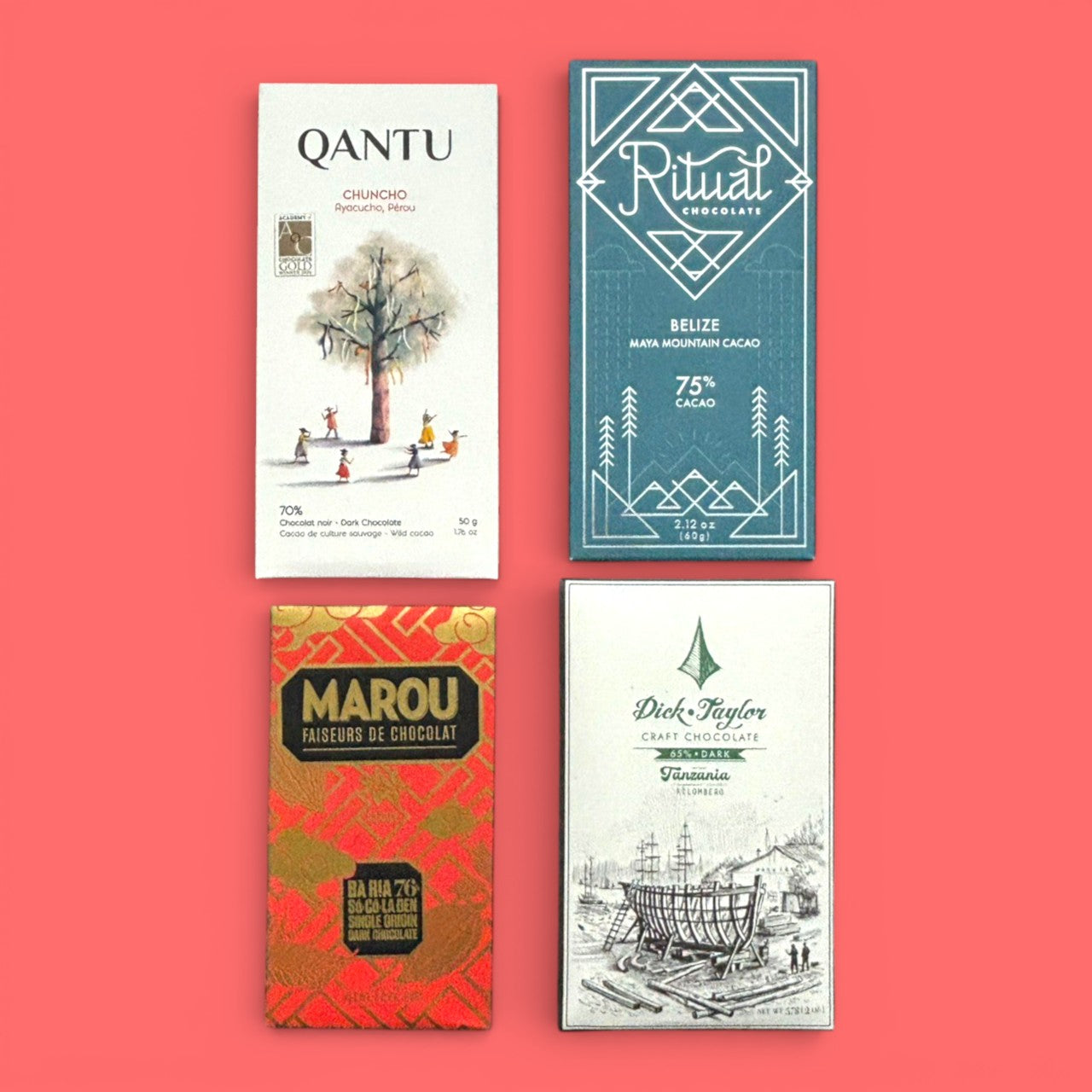

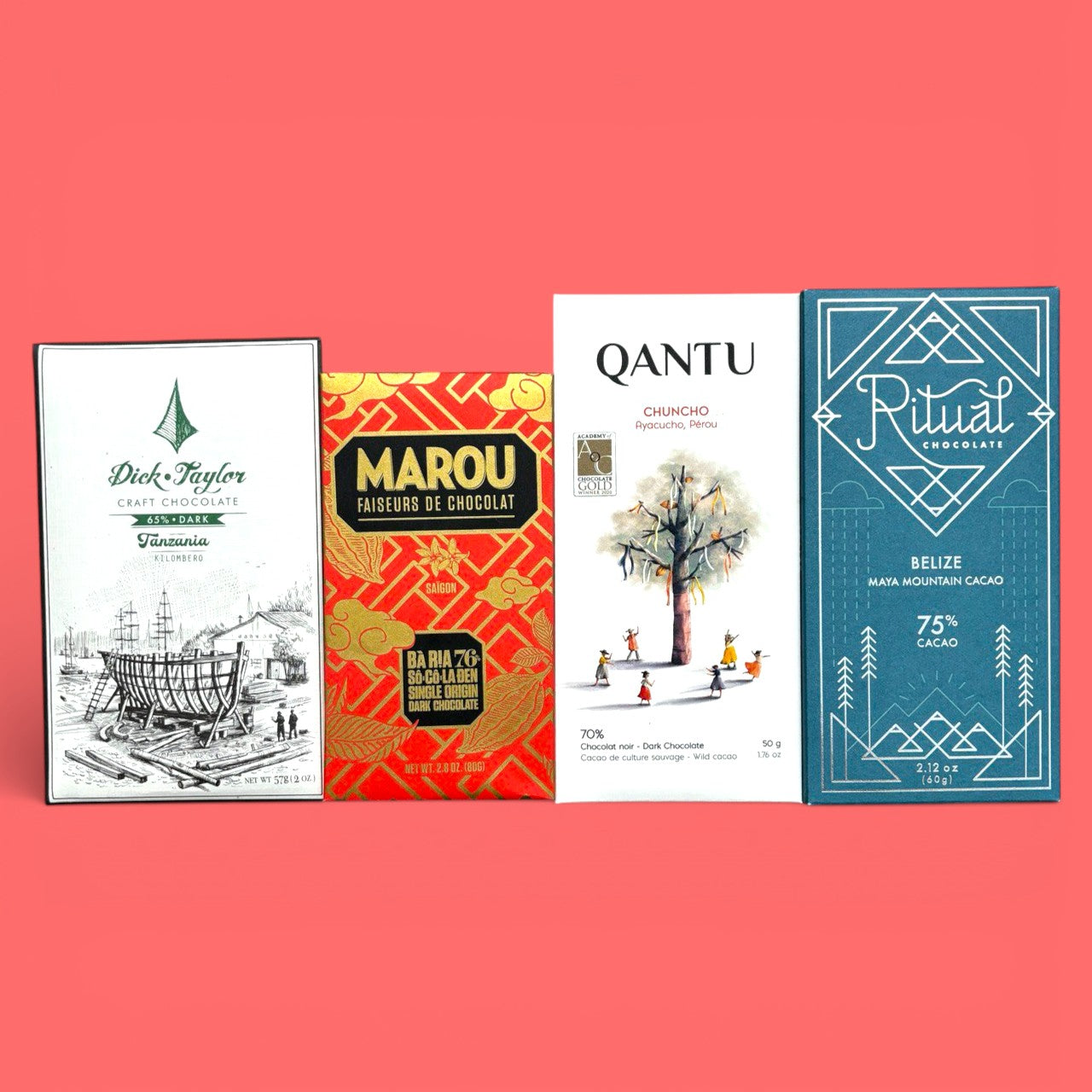

What chocolate are you eating from other makers these days?

For single origin, you really can’t beat SoMa. Those guys are insanely talented, and they’re super super nice! I will always have great things to say about them. For flavored bars, I really love Patric - he made a raspberry balsamic pear bar a while back that almost made me cry, it was so good.

For someone trying LetterPress Chocolate for the first time, what chocolate bar would you give them to try?

Depends on who it is - if it’s someone extremely new to craft chocolate, we usually start people off with our Ghana or Costa Rica bars. Those are the most accessible. To those who are craft chocolate experts, we’d recommend our Ucayali.

What does the future hold for LetterPress Chocolate?

Well, I’ve been saying since we started the company - I don’t want to be wrapping bars at 3 am when I’m in my 60s. So, scaling up is something that we’ve been thinking a lot about lately. We’re running out of room in our current space. We’re also starting to run out of power - and we need more of each in order to scale up further. We’ll probably start looking for a bigger space soon and definitely bring on more people.

Photo Credit LetterPress Chocolate

We want to thank David for taking the time to answer our questions, and we hope you learned more about David and LetterPress Chocolate!

You can view the entire LetterPress Chocolate collection here.